Motherson SAS

Motherson SAS – Integrated Assemblies Division

Motherson SAS, formerly known as SAS Autosystemtechnik, is a global leader in providing integrated module solutions for the automotive industry. Specialising in assembly, logistics, testing, and engineering, MSAS became part of the Motherson Group in August 2023, forming the Integrated Assemblies Division of the Group.

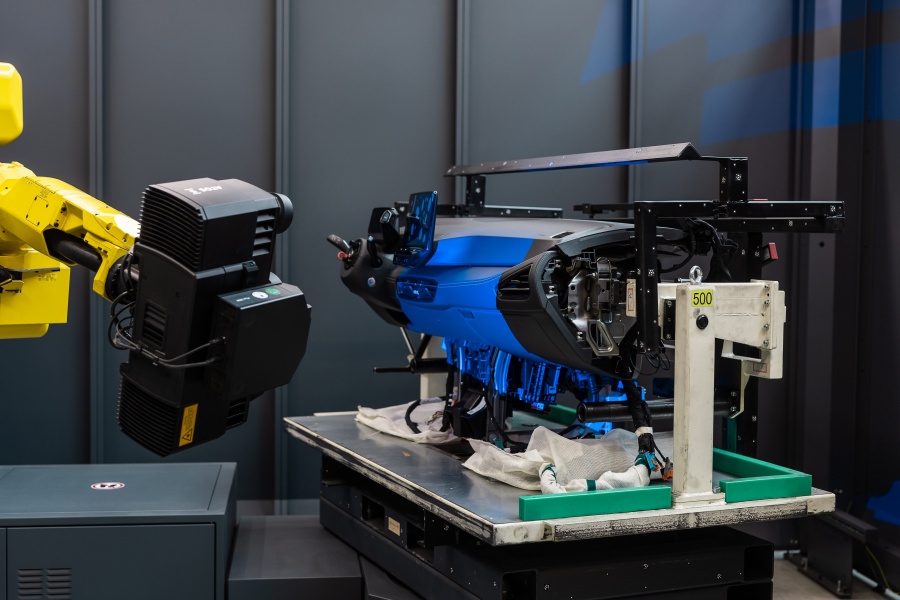

Our expertise lies in delivering safety-critical and complex applications, including cockpit systems, centre consoles, door panels, headliners, and front-end assemblies. As a pioneer in cockpit module integration, we play a pivotal role in an ever-evolving automotive sector. With a steadfast commitment to stringent quality standards, we offer innovative solutions that meet the demands of modern vehicle architecture, including advanced safety-critical modules like bumpers, front-end modules, and more.

Our operations are strategically designed around three core

principles: customer proximity, just-in-sequence delivery, and

compatibility with modular vehicle architecture. As a "Tier 0.5 supplier,"

we collaborate closely with our customers to manage the manufacturing

and seamless integration of major modules into vehicle assembly processes.

This approach ensures production efficiency, adaptability to evolving

program needs, and a streamlined supply chain.

With strong partnerships across leading European, American,

and Chinese OEMs, MSAS is uniquely positioned to meet the

growing global demand for advanced automotive components.

Our continued expansion in Europe, the Americas, and China

underscores our commitment to innovation and excellence. Backed

by deep technical expertise and a focus on product and process

engineering, we deliver solutions that cater to diverse customer

requirements worldwide.